Production

The raw material used for the production of multiply solid board consists 100% of recycled wastepaper bought from collectors of our region and from the rest of the country. This material is stored in our factory selected by type or quality. Multiply solid board consists of five superimposed sheets or plies; the two outer ones are called “liners”, and the three inner ones are called "fillers". There are, accordingly, two independent lines of pulp preparation for making liners and fillers plies.

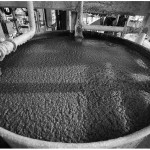

The stock preparation for each of these lines begins with treatment of the wastepaper in rotary autoclaves, which is mixed up with water and heated during 60 minutes with direct steam at 120º C. This enables recycled paper to be crumbled and deodorized, and impurities to be dissolved -these are later eliminated with the pulp washing in rotary thickeners. Next, follows a phase of primary defibering, depuration by hydrocyclones or screens (of holes or grooves), where light and/or heavy solid impurities are removed.

The next stage is a secondary defibering and depuration, where very small solid impurities are removed, after which the pulp is sent to stock tanks. Various chemical additives are added to the pulp, which is ready to enter the multiply board machine so as to provide special qualities to the solid board (impermeability, color, smoothness, whiteness, dry-strength improvements).

The pulp is then sent to the multiply board machines, where five plies are formed separately and then they join each other, beginning with the first ply, to which the next four ones adhere. The five plies joined in only one sheet are supported by a felt and continuously pass to the press section. By way of mechanical pressure, up to 55% of the water in the sheet is removed.

Subsequently, the wet sheet of board passes to the drying section by heating through dryer cylinders fed with steam at approximately 145º C, which enables the reduction of board humidity up to 6-8% -this being the value in equilibrium with the environment in normal average temperature and humidity conditions.

At the end of the machine, the continuous board sheet may pass through a sheet-cutting machine, which supply different final patterns of the sheets to be commercialized, or else, make reels, which are converted –in a following step- in another reel of lesser width.